- #GE LOGICMASTER 6 SOFTWARE#

- #GE LOGICMASTER 6 CODE#

- #GE LOGICMASTER 6 SERIES#

- #GE LOGICMASTER 6 ZIP#

#GE LOGICMASTER 6 SOFTWARE#

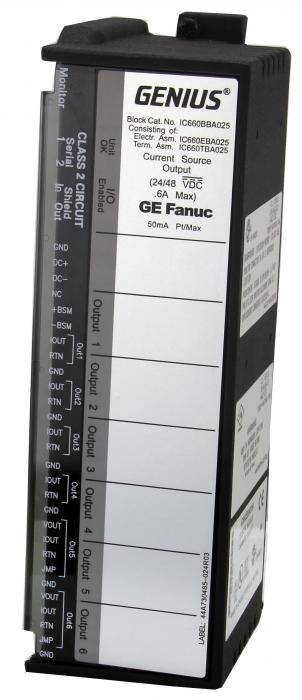

When you work with us, you will find the GE Fanuc software and other products that are compatible with your systems. function block (FB) in a ladder program from the main program created in ladder form, as an application program. SNP Monitor! SNP Monitor! is a tool that allow to: - connect to GE Fanuc PLC, - view and edit values of variables, - write PLC memory to MySQL database, - read values from database and write them to PLC memory, - build free Human Machine Interface using web pages.

#GE LOGICMASTER 6 CODE#

You will be able to write effective programs in just a few code lines. With VersaPro, you can: Create PLC logic and information associated with that logic in a folder.

“C” programming enables users to handle complex calcula-tions that were once only handled by large PLCs. This site is DEDICATED to the teaching of PLC programming. It’s straightforward approach to programming by combining logic with messaging and networking. Page : It lets you create a page and call it in your main block of PLC program, just like Functions and Functional Blocks can be called in main Organization Block GEM 80 PLC Systems and Programming Devices.

This is one of the leading automation firms in the world, you can meet its PLC anywhere, machinery and equipment, I personally see it in robot arms or plastic molding machines, stamping machine …. (no fine print) Ready to go?Ĭlick here to get a quote.Beckhoff Software. We guarantee that your program will be converted correctly. Your program will include file extensions such as: LAD, NAM, EXP.

#GE LOGICMASTER 6 ZIP#

Save the program (.*) as a zip or 7-zip file. Typical conversion turn around time: 5 business days This includes remapping the I/O if possible. We convert your program, review it for accuracy, and manually cleanup the logic so that you can download it and start testing. GE6_program GE6_CLx (a picture's worth a thousand words) Miscellaneous

If we are remapping the I/O you must include the I/O address mapping.

#GE LOGICMASTER 6 SERIES#

The GE Series Six I/O is configured on the backplane DIP switches. You must provide the CLx I/O configuration and remap cross reference. NONE: I/O addresses stay at their O, I, and R addressĪN-X: I/O addresses will be remapped to an AN-X-GENI module (See ProSoft under Resources).ġ756: I/O addresses will be remapped to 1756 I/O. Here are three options for remapping the I/O: These aliases will be renamed and noted in the conversion log. Some characters cannot be used in tag names. DocumentationĪll documentation converts with the following exceptions: When the conversion utility comes to a SUBTRACT instruction with the Trash Register as the result (Register C), the SUBTRACT instruction is replaced with a Less-Than instruction. You can enter an optional "Trash Register" to help with cleanup. They will be noted in the conversion log. Some instructions convert but have additional logic added by the conversion utility to emulate the original instruction. Most instructions will convert without any issues. The ladder logic is converted using Smart Translation Technology. For example, timer R00901 will become T0901. Timers and counters will have new tags created of type TIMER and COUNTER. For example AO0017 will become R.0, AI0017 will become R.0 and O2+1000 will become R.7. Auxiliary I/O will convert to it's base R register. DataĮach register will be converted into a one-dimentional array of identical data type (O,I,R as INT). This utility converts (migrates, translates) GE Series Six (GE6) programs that were created with the Logicmaster 6 (LM6) programming software to Studio 5000, in other words GE6 to ControlLogix (CLx).

0 kommentar(er)

0 kommentar(er)